35Khz Toast Ultrasonic Handheld Cutter Handheld Ultrasonic Cutting Knife for Bread Cutting

| Machine | Ultrasonic handheld Cutter |

| Frequency(KHz) | 35Khz |

| Power | 100 W |

| Cutting Blade / Horn | High speed steel |

| Voltage(V) | 220V |

| The width of blade | 210mm |

| Cutting thickness | any thickness |

| Horn amplitude | 10-40μm |

| Equipment weight | 0.5KG |

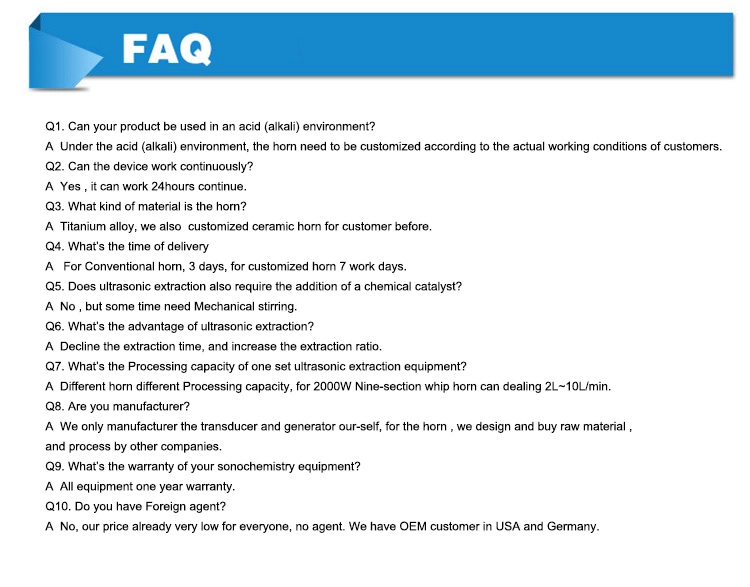

What's the principle of ultrasonic cutting?

The principle of an ultrasonic cutter is completely different from conventional one. It uses the energy of ultrasonic to melt the material to be cut. Therefore, the ultrasonic cutting does not require a sharp cutting edge, nor does it require a large pressure, and does not cause any chipping or breakage. At the same time, since the cutting blade is subjected to ultrasonic vibration, the frictional resistance is particularly small, and the material to be cut is not easily adhered to the blade. This is particularly effective for cutting viscous and elastic materials, frozen materials such as food, rubber, etc., or objects that are inconvenient to apply pressure.

if have ever struggled with cutting thick crunchy loafs of bread, there may be a new knife for you that utilizes ultrasonic technology. Rps-sonic has released video showing how effortlessly their new knife can cut through a loaf of bread, just like butter! Ultrasonic cutting knife can cut the perfect bread slice may soon be over.

https://youtu.be/NWQ6hk-8oQI

Whether you're in the market for a super sharp blade or not, this video is pretty mesmerizing to watch. Traditional bread knifes are serrated, but this knife uses ultrasonic vibrations to cut through whatever you want with ease.

Ultrasonic knifes have held wide indentation in the textile and food industries in recent years. Ultrasonic cutting systems can be used for the precise clipping of textiles, rubber, thermoplastic foil, woven and non-woven fabrics, as well as various kinds of food. There are both mobile handheld units and systems that can be integrated into automated machinery.

The advantages of ultrasonic vibrating blades are: very precise cuts, pressure-free cutting, whereby a deformation of the cutted material (e.g. cake) can be avoided, simultaneous welding of the cutting edge of certain materials, very high cutting speeds and significantly reduced cleaning costs.

Cake,Sandwich, biscuit, wafer, nougat

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars